EHCSF444002S

€14.79

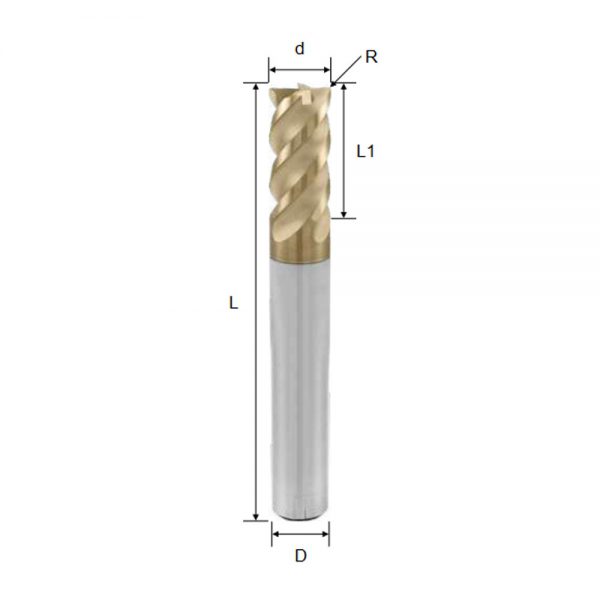

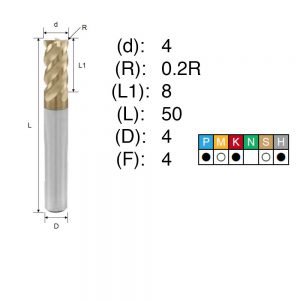

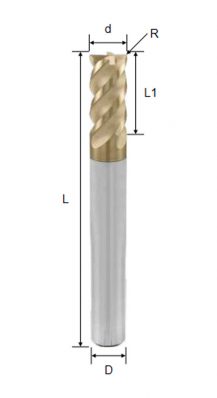

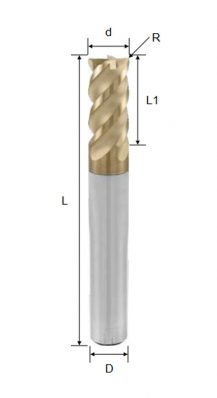

(d): 4

(R): 0.2R

(L1): 8

(L): 50

(D): 4

(F): 4

- Series Specifications

- Description

- Material Chart

- Additional information

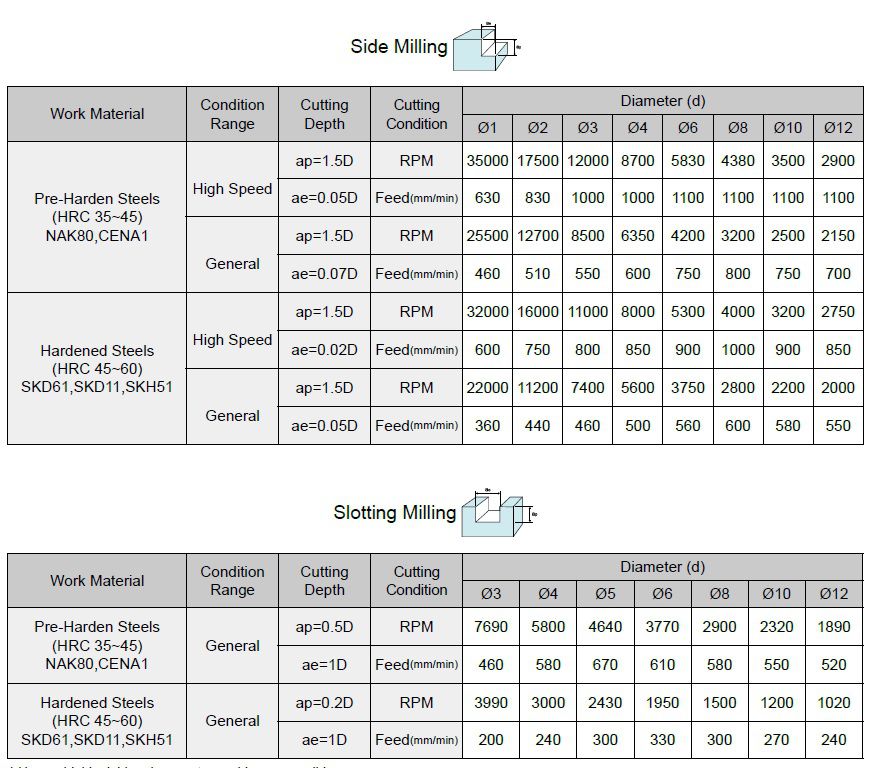

- Cutting Conditions

Series Specifications

| Product No. | Diameter (d) | Corner Radius (R) | CL (L1) | OAL (L) |

Shank (D) |

Flutes (F) |

|---|---|---|---|---|---|---|

| EHCSF441001S | 1.0 | 0.1R | 2 | 50 | 4 | 4 |

| EHCSF441002S | 1.0 | 0.2R | 2 | 50 | 4 | 4 |

| EHCSF441501S | 1.5 | 0.1R | 3 | 50 | 4 | 4 |

| EHCSF441502S | 1.5 | 0.2R | 3 | 50 | 4 | 4 |

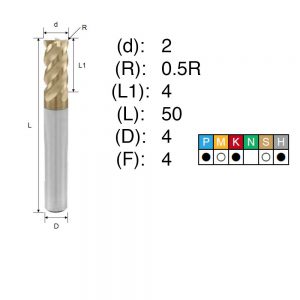

| EHCSF442001S | 2.0 | 0.1R | 4 | 50 | 4 | 4 |

| EHCSF442002S | 2.0 | 0.2R | 4 | 50 | 4 | 4 |

| EHCSF442005S | 2.0 | 0.5R | 4 | 50 | 4 | 4 |

| EHCSF443002S | 3.0 | 0.2R | 6 | 50 | 4 | 4 |

| EHCSF443005S | 3.0 | 0.5R | 6 | 50 | 4 | 4 |

| EHCSF403005S | 3.0 | 0.5R | 6 | 50 | 6 | 4 |

| EHCSF444002S | 4.0 | 0.2R | 8 | 50 | 4 | 4 |

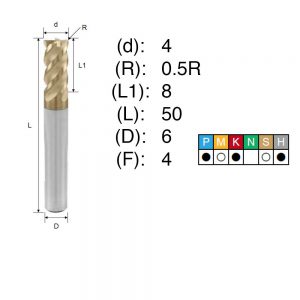

| EHCSF444005S | 4.0 | 0.5R | 8 | 50 | 4 | 4 |

| EHCSF404005S | 4.0 | 0.5R | 8 | 50 | 6 | 4 |

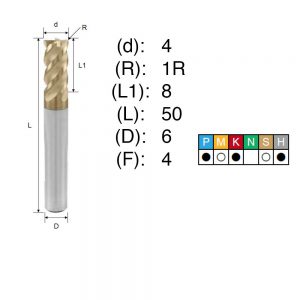

| EHCSF404010S | 4.0 | 1.0R | 8 | 50 | 6 | 4 |

| EHCSF406005S | 6.0 | 0.5R | 12 | 50 | 6 | 4 |

| EHCSF406010S | 6.0 | 1.0R | 12 | 50 | 6 | 4 |

| EHCSF406002S | 6.0 | 0.2R | 12 | 50 | 6 | 4 |

| EHCSF406003S | 6.0 | 0.3R | 12 | 50 | 6 | 4 |

| EHCSF408005S | 8.0 | 0.5R | 16 | 60 | 8 | 4 |

| EHCSF408010S | 8.0 | 1.0R | 16 | 60 | 8 | 4 |

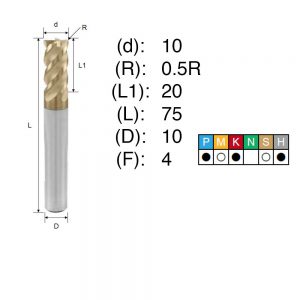

| EHCSF410005S | 10.0 | 0.5R | 20 | 75 | 10 | 4 |

| EHCSF410010S | 10.0 | 1.0R | 20 | 75 | 10 | 2 |

| EHCSF412005S | 12.0 | 0.5R | 24 | 75 | 12 | 2 |

| EHCSF412010S | 12.0 | 1.0R | 24 | 75 | 12 | 2 |

Description

Description

EHCSF444002S – Solid Carbide Endmill

High Precision ∙ Corner Radius ∙ 4F

Diameter (d): 4

Corner Radius (R): 0.2R

CL (L1): 8

OAL (L): 50

Shank (D): 4

Flutes (F): 4

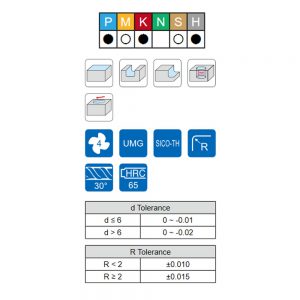

Suitable for HRC 50 and over HRC 50 Hardened Steel, also maximum up to HRC 65.

Ultra grain carbide rods with better abrasion resistance.

Special geometry design, suitable for high hardened working materials.

Material Chart

| Material Group | Description | Content | Tensile Strength (MPa)* | Hardness (HB) | Hardness (HRC) | DIN Standards |

|---|---|---|---|---|---|---|

| P1 | Low-Carbon Steels | C < 0.25% | < 530 | < 125 | - | C15, Ck22, ST37-2, S235JR, 9SMnPb28, GS38 |

| P2 | Medium-Carbon Steels, High-Carbon Steels | C > 0.25% | < 530 | < 220 | < 25 | ST52, S355JR, C35, GS60, Cf53 |

| P3 | Alloy Steels, Tool Steels | C > 0.25% | 600 ~ 850 | < 330 | < 35 | 16MnCr5, Ck45, 21CrMoV5-7, 38SMn28 |

| P4 | Alloy Steels, Tool Steels | C > 0.25% | 800 ~ 1000 | 350 ~ 450 | 35 ~ 48 | 100Cr6, 105MnCr4, 51CrMnV4, 105WCr6, 100Cr2 |

| P5 | Ferritic, Martensitic, PH Stainless Steels | C = 0~0.4% | 600 ~ 850 | < 330 | < 35 | X6Cr13, X10Cr13, X20Cr13, X12CrMoS17, X20CrMo13 |

| P6 | Austenitic Stainless Steel | C = 0.1~0.6% | 900 ~ 1350 | 350 ~ 450 | 35 ~ 48 | X40CrMoV51, H1, X155CrVMo121, S6-5-2-5, X45Cr13, X120Mn12 |

| M1 | Austenitic Stainless Steel | C = 0.05~0.15% | < 650 | 130 ~ 200 | - | X5CrNi1810, GX6CrNiMo1810, X6CrNiMoTi17122, X8CrNiMoAl1572 |

| M2 | High-Strength Austenitic Stainless and Cast Stainless Steels | C = 0.05~0.15% | 500 ~ 700 | 150 ~ 230 | < 25 | X2CrNiMo134, X10CrNi189, X5CrNiCuNb1744 |

| M3 | Duplex Stainless Steel | C = 0.05~0.2% | < 900 | 135 ~ 275 | < 30 | X2CrNiMoN2315, X20CrNiSi254, GX40CrNiSi274, X2CrNiMoN2253 |

| K1 | Grey Cast Iron | - | 150 ~ 400 | 120 ~ 290 | < 32 | GG10, GG15, GG20, GG25, GG40 |

| K2 | Low- and Medium-Strength Ductile Irons and Compacted Graphite Irons (CGI) | - | 400 ~ 600 | 130 ~ 260 | < 28 | GGG35.3, GGG40.3, GGG70 |

| K3 | High-Strength Ductile Irons and Austempered Ductile Iron (ADI) | - | 600 ~ 900 | 180 ~ 350 | < 43 | GTW-35-04, GTW-65, GTS-35-10, GTS-45-06 |

| N1 | Wrought Aluminium | - | < 520 | 60 ~ 90 | < 43 | AIMg1, AI99.5, AICuMg1, AICuBiPb, AIMgSi1, ALMgSiPb |

| N2 | Low-Silicon Aluminium Alloys | Si < 12.2% | < 350 | 70 ~ 120 | < 43 | GAISiCu4, GDAISi10Mg |

| N3 | High-Silicon Aluminium Alloys | Si < 12.2% | 200 ~ 320 | 60 ~ 120 | < 43 | G-ALSi12, G-AlSi17Cu4, G-AISi21CuNiMg |

| N4 | Copper and Copper Alloys | - | 200 ~ 650 | 60 ~ 200 | < 43 | CuZn40, Ms60, G-CuSn5ZnPb, CuZn37, CuSi3Mn |

| N5 | Nylon, Plastics | - | - | - | < 43 | Lexan, Hostalen, Polystyrol, Makrolon |

| N6 | Carbon, Graphite Composites, CFRP | - | 600 ~ 1500 | - | < 43 | CFRP, CFK, GFK |

| S1 | Iron-Based, Heat-Resistant Alloys | - | 500 ~ 1200 | 160 ~ 260 | 25 ~ 48 | X1NiCrMoCu32287, X12NiCrSi3616, X5NiCrAITi3120,X40CoCrNi20 20 |

| S2 | Cobalt-Based, Heat-Resistant Alloys | - | 1000 ~ 1450 | 250 ~ 450 | 25 ~ 48 | Haynes 188, Stellite 6, 21, 31 |

| S3 | Nickel-Based, Heat-Resistant Alloys | - | 600 ~ 1700 | 160 ~ 450 | 33 ~ 48 | NiCr29Fe, NiCr22Mo9Nb, NiCr20Mo, NiCr19FeNbMo, NiCr16Fe7TiAl |

| S4 | Titanium and Titanium Alloys | - | - | 300 ~ 400 | 33 ~ 48 | Ti1, TiAI5Sn2, TiAI6V4, TiAI4Mo4Sn2 |

| H1 | Hardened Materials | - | - | < 460 | < 48 | GX260NiCr42, GX330NiCr42, GX300CrNiSi952, GX300CrMo153 |

| H2 | Hardened Materials | - | - | 460 ~ 560 | 48 ~ 55 | - |

| H3 | Hardened Materials | - | - | 560 ~ 650 | 56 ~ 60 | - |

| H4 | Hardened Materials | - | - | > 650 | > 60 | - |