0 ITEMSView cart

EPSST204020U

€24.73

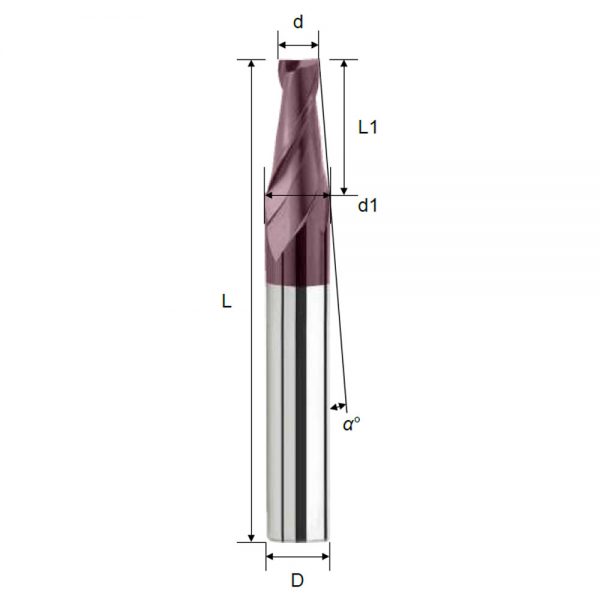

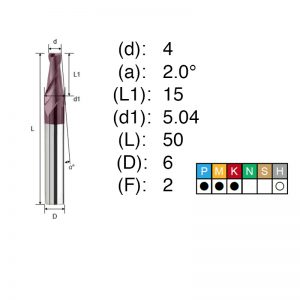

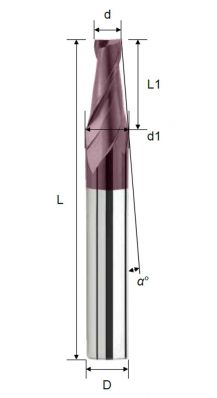

d: 4

α:2.0°

L1: 15

d1: 5.04

L: 50

D: 6

F: 2

- Series Specifications

- Description

- Material Chart

- Additional information

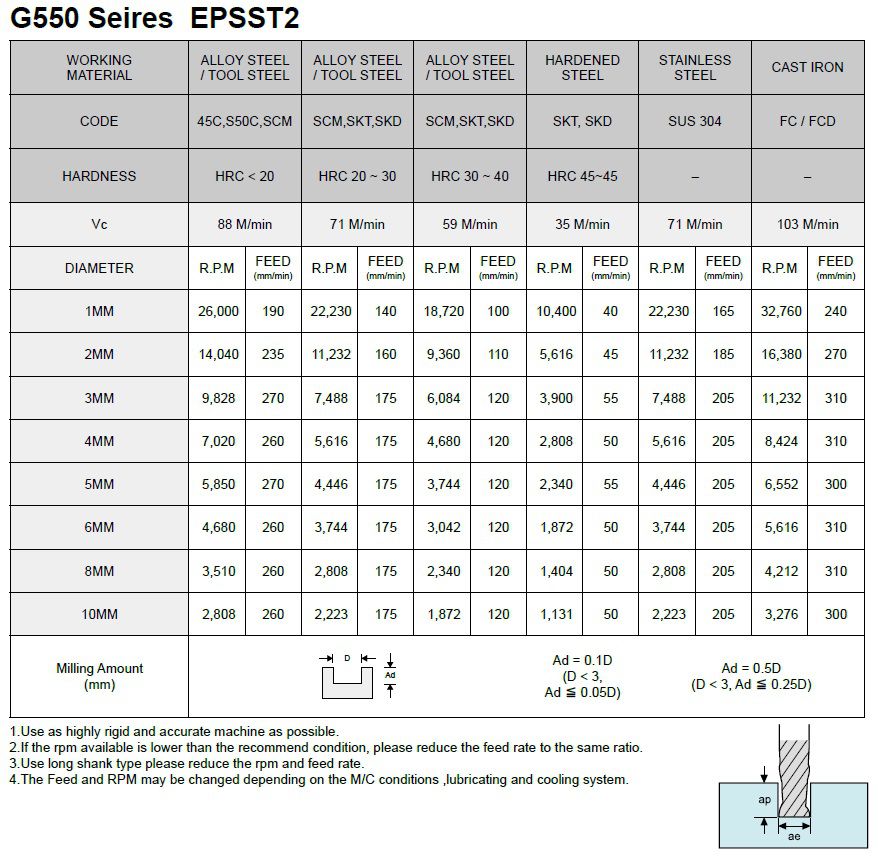

- Cutting Conditions

Series Specifications

| Product No. | Diameter (d) |

α ̊ | CL (L1) |

NL (d1) |

OAL (L) |

Shank (D) |

Flutes (F) |

|---|---|---|---|---|---|---|---|

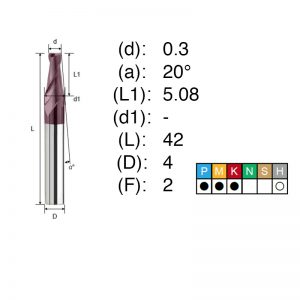

| EPSST24015CU | 0,15 | 20° | 5,29 | - | 42 | 4 | 2 |

| EPSST24030CU | 0,30 | 20° | 5,08 | - | 42 | 4 | 2 |

| EPSST24030DU | 0,30 | 25° | 3,96 | - | 42 | 4 | 2 |

| EPSST24060BU | 0,60 | 15° | 4,50 | - | 42 | 4 | 2 |

| EPSST24060CU | 0,60 | 20° | 4,67 | - | 42 | 4 | 2 |

| EPSST24120CU | 1,20 | 20° | 3,84 | - | 42 | 4 | 2 |

| EPSST241005U | 1,0 | 0.5° | 4,0 | 1,07 | 50 | 4 | 2 |

| EPSST241010U | 1,0 | 1.0° | 4,0 | 1,14 | 50 | 4 | 2 |

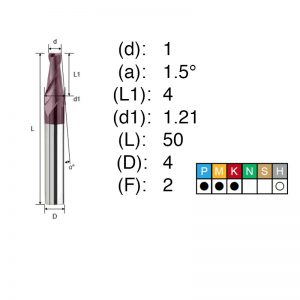

| EPSST241015U | 1,0 | 1.5° | 4,0 | 1,21 | 50 | 4 | 2 |

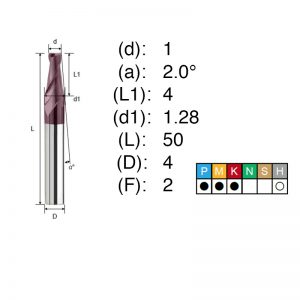

| EPSST241020U | 1,0 | 2.0° | 4,0 | 1,28 | 50 | 4 | 2 |

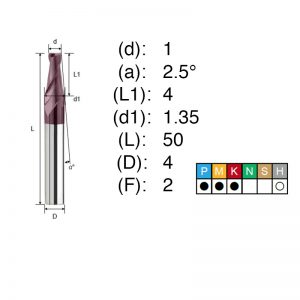

| EPSST241025U | 1,0 | 2.5° | 4,0 | 1,35 | 50 | 4 | 2 |

| EPSST241030U | 1,0 | 3.0° | 4,0 | 1,42 | 50 | 4 | 2 |

| EPSST241050U | 1,0 | 5.0° | 4,0 | 1,70 | 50 | 4 | 2 |

| EPSST241070U | 1,0 | 7.0° | 4,0 | 1,98 | 50 | 4 | 2 |

| EPSST2410A0U | 1,0 | 10.0° | 4,0 | 2,41 | 50 | 4 | 2 |

| EPSST2410A5U | 1,0 | 15.0° | 4,0 | 3,14 | 50 | 4 | 2 |

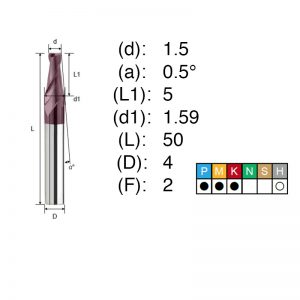

| EPSST241505U | 1,5 | 0.5° | 5,0 | 1,59 | 50 | 4 | 2 |

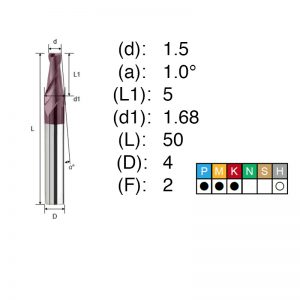

| EPSST241510U | 1,5 | 1.0° | 5,0 | 1,68 | 50 | 4 | 2 |

| EPSST241515U | 1,5 | 1.5° | 5,0 | 1,76 | 50 | 4 | 2 |

| EPSST241520U | 1,5 | 2.0° | 5,0 | 1,85 | 50 | 4 | 2 |

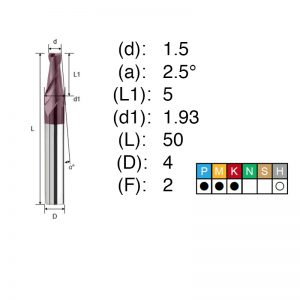

| EPSST241525U | 1,5 | 2.5° | 5,0 | 1,93 | 50 | 4 | 2 |

| EPSST241530U | 1,5 | 3.0° | 5,0 | 2,02 | 50 | 4 | 2 |

| EPSST241550U | 1,5 | 5.0° | 5,0 | 2,37 | 50 | 4 | 2 |

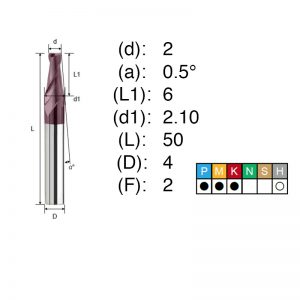

| EPSST242005U | 2,0 | 0.5° | 6,0 | 2,10 | 50 | 4 | 2 |

| EPSST242010U | 2,0 | 1.0° | 6,0 | 2,21 | 50 | 4 | 2 |

| EPSST242015U | 2,0 | 1.5° | 6,0 | 2,31 | 50 | 4 | 2 |

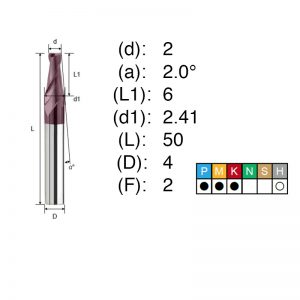

| EPSST242020U | 2,0 | 2.0° | 6,0 | 2,41 | 50 | 4 | 2 |

| EPSST242025U | 2,0 | 2.5° | 6,0 | 2,52 | 50 | 4 | 2 |

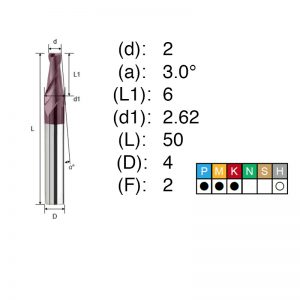

| EPSST242030U | 2,0 | 3.0° | 6,0 | 2,62 | 50 | 4 | 2 |

| EPSST242050U | 2,0 | 5.0° | 6,0 | 3,05 | 50 | 4 | 2 |

| EPSST242070U | 2,0 | 7.0° | 6,0 | 3,47 | 50 | 4 | 2 |

| EPSST2020A0U | 2,0 | 10.0° | 6,0 | 4,11 | 50 | 6 | 2 |

| EPSST2020A5U | 2,0 | 15.0° | 6,0 | 5,22 | 50 | 6 | 2 |

| EPSST242505U | 2,5 | 0.5° | 8,0 | 2,64 | 50 | 4 | 2 |

| EPSST242510U | 2,5 | 1.0° | 8,0 | 2,78 | 50 | 4 | 2 |

| EPSST242515U | 2,5 | 1.5° | 8,0 | 2,91 | 50 | 4 | 2 |

| EPSST242520U | 2,5 | 2.0° | 8,0 | 3,05 | 50 | 4 | 2 |

| EPSST242525U | 2,5 | 2.5° | 8,0 | 3,20 | 50 | 4 | 2 |

| EPSST242530U | 2,5 | 3.0° | 8,0 | 3,33 | 50 | 4 | 2 |

| EPSST242550U | 2,5 | 5.0° | 8,0 | 3,90 | 50 | 4 | 2 |

| EPSST203005U | 3,0 | 0.5° | 10,0 | 3,17 | 50 | 6 | 2 |

| EPSST203010U | 3,0 | 1.0° | 10,0 | 3,35 | 50 | 6 | 2 |

| EPSST203015U | 3,0 | 1.5° | 10,0 | 3,52 | 50 | 6 | 2 |

| EPSST203020U | 3,0 | 2.0° | 10,0 | 3,69 | 50 | 6 | 2 |

| EPSST203025U | 3,0 | 2.5° | 10,0 | 3,87 | 50 | 6 | 2 |

| EPSST203030U | 3,0 | 3.0° | 10,0 | 4,05 | 50 | 6 | 2 |

| EPSST203050U | 3,0 | 5.0° | 10,0 | 4,75 | 50 | 6 | 2 |

| EPSST203070U | 3,0 | 7.0° | 12,0 | 6,00 | 50 | 6 | 2 |

| EPSST2030A0U | 3,0 | 10.0° | 12,0 | 7,22 | 60 | 8 | 2 |

| EPSST2030A5U | 3,0 | 15.0° | 12,0 | 9,40 | 75 | 10 | 2 |

| EPSST204005U | 4,0 | 0.5° | 15,0 | 4,26 | 50 | 6 | 2 |

| EPSST204010U | 4,0 | 1.0° | 15,0 | 4,52 | 50 | 6 | 2 |

| EPSST204015U | 4,0 | 1.5° | 15,0 | 4,79 | 50 | 6 | 2 |

| EPSST204020U | 4,0 | 2.0° | 15,0 | 5,04 | 50 | 6 | 2 |

| EPSST204025U | 4,0 | 2.5° | 15,0 | 5,31 | 50 | 6 | 2 |

| EPSST204030U | 4,0 | 3.0° | 15,0 | 5,57 | 50 | 6 | 2 |

| EPSST204050U | 4,0 | 5.0° | 15,0 | 6,62 | 60 | 8 | 2 |

| EPSST204070U | 4,0 | 7.0° | 16,0 | 8,00 | 60 | 8 | 2 |

| EPSST2040A0U | 4,0 | 10.0° | 17,0 | 10,00 | 75 | 10 | 2 |

| EPSST2040A5U | 4,0 | 15.0° | 14,9 | 12,00 | 75 | 12 | 2 |

| EPSST205005U | 5,0 | 0.5° | 20,0 | 5,34 | 60 | 6 | 2 |

| EPSST205010U | 5,0 | 1.0° | 20,0 | 5,70 | 60 | 6 | 2 |

| EPSST205015U | 5,0 | 1.5° | 19,6 | 6,00 | 60 | 6 | 2 |

| EPSST205020U | 5,0 | 2.0° | 20,0 | 6,39 | 60 | 8 | 2 |

| EPSST205025U | 5,0 | 2.5° | 20,0 | 6,74 | 60 | 8 | 2 |

| EPSST205030U | 5,0 | 3.0° | 20,0 | 7,10 | 60 | 8 | 2 |

| EPSST205050U | 5,0 | 5.0° | 20,0 | 8,50 | 75 | 10 | 2 |

| EPSST205070U | 5,0 | 7.0° | 20,0 | 10,00 | 75 | 10 | 2 |

| EPSST2050A0U | 5,0 | 10.0° | 20,0 | 12,00 | 75 | 12 | 2 |

| EPSST206005U | 6,0 | 0.5° | 20,0 | 6,35 | 60 | 8 | 2 |

| EPSST206010U | 6,0 | 1.0° | 20,0 | 6,70 | 60 | 8 | 2 |

| EPSST206015U | 6,0 | 1.5° | 20,0 | 7,05 | 60 | 8 | 2 |

| EPSST206020U | 6,0 | 2.0° | 20,0 | 7,40 | 60 | 8 | 2 |

| EPSST206025U | 6,0 | 2.5° | 20,0 | 7,75 | 60 | 8 | 2 |

| EPSST206030U | 6,0 | 3.0° | 20,0 | 8,10 | 75 | 10 | 2 |

| EPSST206050U | 6,0 | 5.0° | 20,0 | 9,50 | 75 | 10 | 2 |

| EPSST206070U | 6,0 | 7.0° | 24,0 | 12,00 | 75 | 12 | 2 |

| EPSST2060A0U | 6,0 | 10.0° | 22,0 | 14,00 | 75 | 14 | 2 |

| EPSST208005U | 8,0 | 0.5° | 25,0 | 8,44 | 75 | 10 | 2 |

| EPSST208010U | 8,0 | 1.0° | 25,0 | 8,87 | 75 | 10 | 2 |

| EPSST208015U | 8,0 | 1.5° | 25,0 | 9,31 | 75 | 10 | 2 |

| EPSST208020U | 8,0 | 2.0° | 25,0 | 9,75 | 75 | 10 | 2 |

| EPSST208030U | 8,0 | 3.0° | 25,0 | 10,62 | 75 | 12 | 2 |

| EPSST208050U | 8,0 | 5.0° | 25,0 | 12,37 | 75 | 14 | 2 |

| EPSST208070U | 8,0 | 7.0° | 32,0 | 16,00 | 100 | 16 | 2 |

| EPSST2080A0U | 8,0 | 10.0° | 28,0 | 18,00 | 100 | 18 | 2 |

| EPSST210005U | 10,0 | 0.5° | 35,0 | 10,61 | 75 | 12 | 2 |

| EPSST210010U | 10,0 | 1.0° | 35,0 | 11,22 | 75 | 12 | 2 |

| EPSST210015U | 10,0 | 1.5° | 35,0 | 11,83 | 75 | 12 | 2 |

| EPSST210020U | 10,0 | 2.0° | 35,0 | 12,44 | 75 | 14 | 2 |

| EPSST210030U | 10,0 | 3.0° | 35,0 | 13,67 | 75 | 14 | 2 |

| EPSST210050U | 10,0 | 5.0° | 34,2 | 16,00 | 100 | 16 | 2 |

Description

Description

EPSST204020U – Solid Carbide Endmill

Taper ∙ Square ∙ 2F

Diameter (d): 4

α: 2.0°

CL (L1): 15

NL (d1): 5.04

OAL (L): 50

Shank (D): 6

Flutes (F): 2

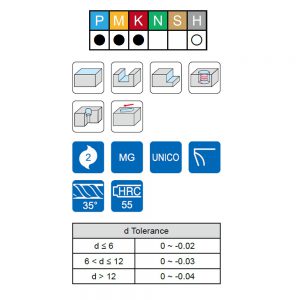

Suitable for HRC 30 to HRC 55 Ordinary Steel, Alloy Steel, Cast Iron, Heat-Resistant Steel, etc.

High strength of taper cutting length, can cut deep grooves without breaking.

Convenient for Tap cutting in 3 axis machine.

Material Chart

| Material Group | Description | Content | Tensile Strength (MPa)* | Hardness (HB) | Hardness (HRC) | DIN Standards |

|---|---|---|---|---|---|---|

| P1 | Low-Carbon Steels | C < 0.25% | < 530 | < 125 | - | C15, Ck22, ST37-2, S235JR, 9SMnPb28, GS38 |

| P2 | Medium-Carbon Steels, High-Carbon Steels | C > 0.25% | < 530 | < 220 | < 25 | ST52, S355JR, C35, GS60, Cf53 |

| P3 | Alloy Steels, Tool Steels | C > 0.25% | 600 ~ 850 | < 330 | < 35 | 16MnCr5, Ck45, 21CrMoV5-7, 38SMn28 |

| P4 | Alloy Steels, Tool Steels | C > 0.25% | 800 ~ 1000 | 350 ~ 450 | 35 ~ 48 | 100Cr6, 105MnCr4, 51CrMnV4, 105WCr6, 100Cr2 |

| P5 | Ferritic, Martensitic, PH Stainless Steels | C = 0~0.4% | 600 ~ 850 | < 330 | < 35 | X6Cr13, X10Cr13, X20Cr13, X12CrMoS17, X20CrMo13 |

| P6 | Austenitic Stainless Steel | C = 0.1~0.6% | 900 ~ 1350 | 350 ~ 450 | 35 ~ 48 | X40CrMoV51, H1, X155CrVMo121, S6-5-2-5, X45Cr13, X120Mn12 |

| M1 | Austenitic Stainless Steel | C = 0.05~0.15% | < 650 | 130 ~ 200 | - | X5CrNi1810, GX6CrNiMo1810, X6CrNiMoTi17122, X8CrNiMoAl1572 |

| M2 | High-Strength Austenitic Stainless and Cast Stainless Steels | C = 0.05~0.15% | 500 ~ 700 | 150 ~ 230 | < 25 | X2CrNiMo134, X10CrNi189, X5CrNiCuNb1744 |

| M3 | Duplex Stainless Steel | C = 0.05~0.2% | < 900 | 135 ~ 275 | < 30 | X2CrNiMoN2315, X20CrNiSi254, GX40CrNiSi274, X2CrNiMoN2253 |

| K1 | Grey Cast Iron | - | 150 ~ 400 | 120 ~ 290 | < 32 | GG10, GG15, GG20, GG25, GG40 |

| K2 | Low- and Medium-Strength Ductile Irons and Compacted Graphite Irons (CGI) | - | 400 ~ 600 | 130 ~ 260 | < 28 | GGG35.3, GGG40.3, GGG70 |

| K3 | High-Strength Ductile Irons and Austempered Ductile Iron (ADI) | - | 600 ~ 900 | 180 ~ 350 | < 43 | GTW-35-04, GTW-65, GTS-35-10, GTS-45-06 |

| N1 | Wrought Aluminium | - | < 520 | 60 ~ 90 | < 43 | AIMg1, AI99.5, AICuMg1, AICuBiPb, AIMgSi1, ALMgSiPb |

| N2 | Low-Silicon Aluminium Alloys | Si < 12.2% | < 350 | 70 ~ 120 | < 43 | GAISiCu4, GDAISi10Mg |

| N3 | High-Silicon Aluminium Alloys | Si < 12.2% | 200 ~ 320 | 60 ~ 120 | < 43 | G-ALSi12, G-AlSi17Cu4, G-AISi21CuNiMg |

| N4 | Copper and Copper Alloys | - | 200 ~ 650 | 60 ~ 200 | < 43 | CuZn40, Ms60, G-CuSn5ZnPb, CuZn37, CuSi3Mn |

| N5 | Nylon, Plastics | - | - | - | < 43 | Lexan, Hostalen, Polystyrol, Makrolon |

| N6 | Carbon, Graphite Composites, CFRP | - | 600 ~ 1500 | - | < 43 | CFRP, CFK, GFK |

| S1 | Iron-Based, Heat-Resistant Alloys | - | 500 ~ 1200 | 160 ~ 260 | 25 ~ 48 | X1NiCrMoCu32287, X12NiCrSi3616, X5NiCrAITi3120,X40CoCrNi20 20 |

| S2 | Cobalt-Based, Heat-Resistant Alloys | - | 1000 ~ 1450 | 250 ~ 450 | 25 ~ 48 | Haynes 188, Stellite 6, 21, 31 |

| S3 | Nickel-Based, Heat-Resistant Alloys | - | 600 ~ 1700 | 160 ~ 450 | 33 ~ 48 | NiCr29Fe, NiCr22Mo9Nb, NiCr20Mo, NiCr19FeNbMo, NiCr16Fe7TiAl |

| S4 | Titanium and Titanium Alloys | - | - | 300 ~ 400 | 33 ~ 48 | Ti1, TiAI5Sn2, TiAI6V4, TiAI4Mo4Sn2 |

| H1 | Hardened Materials | - | - | < 460 | < 48 | GX260NiCr42, GX330NiCr42, GX300CrNiSi952, GX300CrMo153 |

| H2 | Hardened Materials | - | - | 460 ~ 560 | 48 ~ 55 | - |

| H3 | Hardened Materials | - | - | 560 ~ 650 | 56 ~ 60 | - |

| H4 | Hardened Materials | - | - | > 650 | > 60 | - |